AAPI Pressure Vessel Inspections - Optimizing Mechanical Integrity and Operational Safety

EARTHRES, a Division of RESPEC, specializes in API Pressure Vessel Services, playing a vital role in managing Mechanical Integrity Programs for industrial or oil & gas clients. Through the use of advanced inspection techniques and industry-leading methodologies, EARTHRES ensures the safety, reliability, and longevity of pressurized equipment, helping clients maintain optimal performance and compliance.

The Challenges

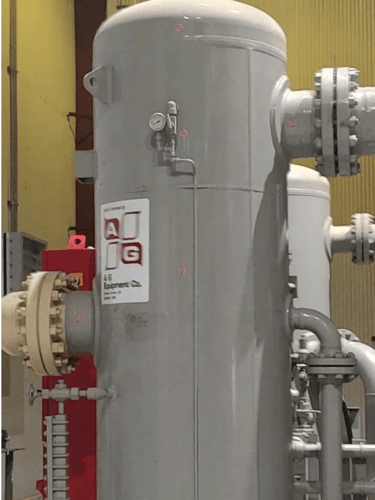

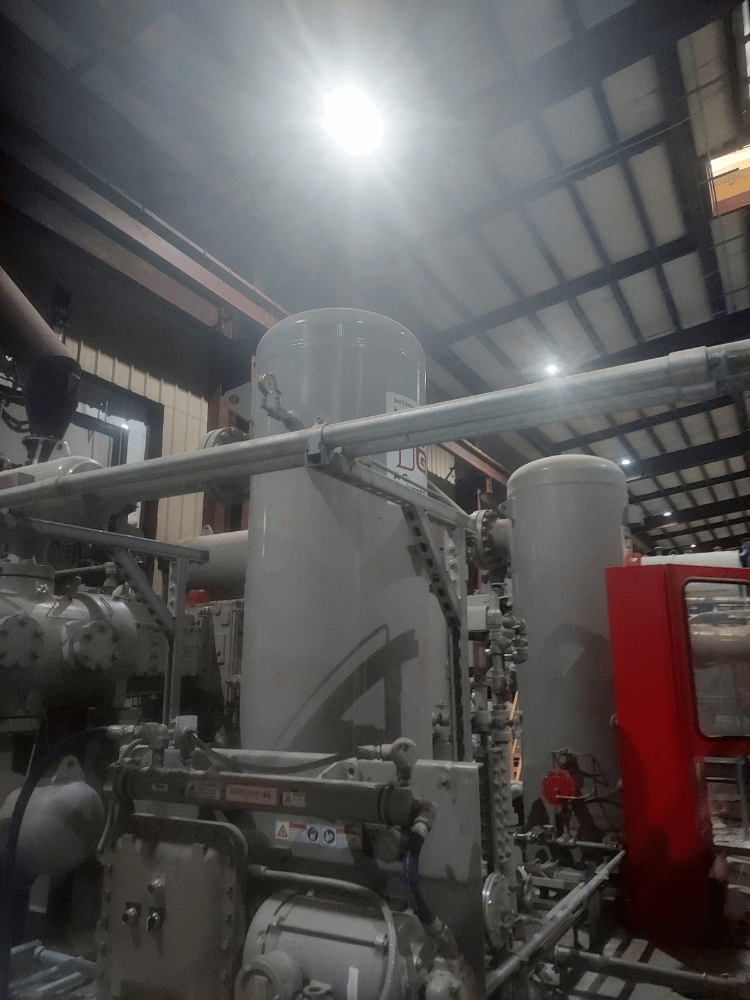

Pressure vessels are widely used in industries such as oil and gas, power generation, and processing plants. Many of the Oil & Gas facilities may include 100-400 pressure vessels requiring routine inspection and maintenance as part of the mechanical integrity programs required by OSHA process safety management (PSM) and good engineering practices.

One of our clients manages over 30 compressor stations, each demanding rigorous inspection schedules as part of their Mechanical Integrity and Preventative Maintenance Programs. These inspections include baseline ultrasonic testing to determine the vessel wall thickness and corrosion rates, external inspections every 5-10 years per API guidelines, and internal inspections every 10-20 years, depending on the baseline data and risk analysis.

Additional challenges include equipment that has been out of service but is now being considered for reuse. Before these assets can be reintroduced into operation, a Fitness for Service (FFS) Inspection is required. This assessment ensures structural integrity and confirms if the equipment meets fit-for-purpose standards. FFS methods are highly specialized and involve evaluating critical pressurized components and welded elements across multiple industries and asset lifecycles. They provide actionable insights to mitigate risks and recommend repairs or replacements where necessary.

The Solution

EARTHRES adopted a systematic and methodical approach to API Pressure Vessel Inspections, rooted in industry best practices and supported by API-certified inspectors. The process comprised the following key steps:

1. Integrity Management Program Development

EARTHRES collaborated closely with our client to identify and catalog all vessel and equipment on site. This was followed by the execution of nondestructive in-service testing methods that adhered to API standards.

2. Baseline Assessments

Baseline measurements were critical to establishing the condition of each vessel. EARTHRES performed ultrasonic testing, determined corrosion rates, and calculated the remaining useful life of the equipment.

3. Inspection and Risk Mitigation

Routine external and internal inspections were conducted on rotating schedule, ensuring any potential issues were identified before they could escalate into operational failures. When necessary, EARTHRES advised removing a vessel from service to mitigate risks proactively.

4. Fitness for Service (FFS) Assessments

For equipment being evaluated for reuse, EARTHRES conducted detailed FFS assessments. These involved a thorough evaluation of pressurized and welded components to determine their residual fitness for safe use. This analysis provided a quantitative measure of asset integrity and highlighted the need for any repairs or replacements.

5. Optimized Maintenance and Inspection Planning

The comprehensive data collected allowed the optimization of maintenance plans, reduced the likelihood of unnecessary repairs and ensured efficient scheduling of any required downtime.

Results

EARTHRES' API Pressure Vessel Inspections yielded numerous critical benefits for its client:

-

Operational Safety

By proactively identifying and addressing potential issues, the inspections significantly improve plant safety, safeguarding both employees and equipment.

-

Extended Equipment Lifespan

FFS assessments extend the operational life of assets by providing precise data on residual asset life. This ensures assets are utilized to their fullest potential without compromising safety or performance.

-

Improved Planning and Efficiency

EARTHRES enables our client to plan capital expenditures effectively, scheduling maintenance and repair activities strategically to minimize downtime and disruptions.

-

Cost Reduction

By identifying problems early and avoiding unnecessary repairs or replacements, our client experiences a reduction in capital and operational expenditures.

-

Enhanced Reliability and Meeting the Regulatory Requirement

Client benefits from the peace of mind that comes with knowing their equipment is inspected to the highest standards, minimizing unexpected failures and costly operational halts.

EARTHRES' efforts ensure our client can confidently maintain their mechanical integrity while optimizing costs and improving operational efficiency.

Our commitment to excellence in API Pressure Vessel Inspections and Mechanical Integrity Management enables our clients to proactively manage the integrity of their critical assets, ensuring long-term efficiency, safety, and reliability.

Are you facing challenges with your API Pressure Vessel Services?

Let us help! Get in touch with our experts to learn how EARTHRES can ensure the safety and longevity of your pressurized equipment.