CATHODIC PROTECTION SERVICES

Safeguard Your Infrastructure with Expert Care

Have Any Questions?

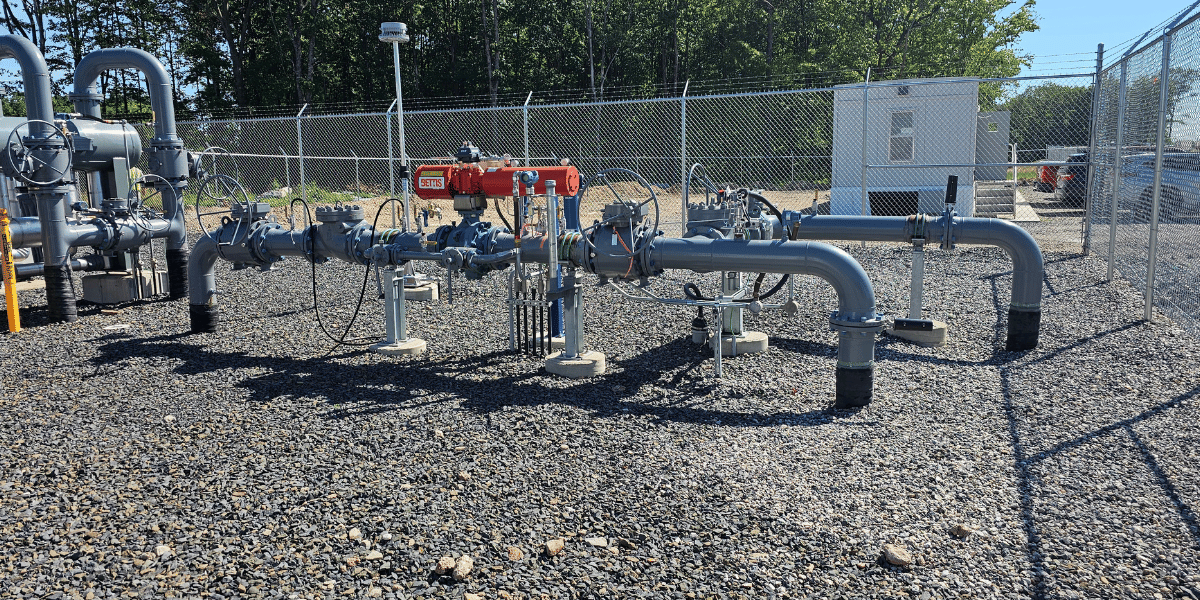

Corrosion is one of the most significant threats to pipeline integrity, causing safety hazards, operational downtime, and costly repairs. At EARTHRES, we help protect your midstream, gathering, and transmission pipelines with our comprehensive Cathodic Protection Systems Engineering Services.

With decades of experience in corrosion prevention, our team ensures your infrastructure remains safe, durable, and compliant. From system design to performance monitoring, we offer end-to-end solutions tailored to your unique operational and environmental needs.

Why Choose EARTHRES for Your Cathodic Protection Needs?

Cathodic protection is a proven technique to prevent corrosion by using sacrificial anodes or impressed currents. This method stops the natural degradation process in metal structures, saving organizations from potential mechanical failures and extending the life of critical assets.

At EARTHRES, we take it a step further with innovative design, precise diagnostics, and continuous maintenance, providing unparalleled protection for your assets.

Our Comprehensive Services

Our multidisciplinary team of corrosion specialists delivers a broad range of services designed to meet the highest industry standards, including:

Atmospheric Corrosion (AC) Assessment and Mitigation:

Identify risks and implement AC interference solutions for enhanced performance.

Annual Cathodic Protection Monitoring Surveys:

Detect issues early with routine monitoring to maintain system efficiency.

Close Interval Surveys:

Gather high-resolution data to pinpoint potential deficiencies in your system.

Impressed Current Cathodic Protection (ICCP) Systems and Sacrificial Anode Systems:

Tailored solutions that align with your operational and environmental needs.

Ground Bed Design:

Safely manage electrical currents with optimized layouts.

Rectifier System Engineering:

Maximize system longevity through robust rectifier designs.

Training for Operator Qualifications:

Equip your team with the skills to handle cathodic protection systems confidently and effectively.

Remote Monitoring Systems:

Monitor systems continually to identify and address issues proactively.

Repairs to Existing Systems:

Extend the life of your infrastructure by addressing system flaws or malfunctions.

Tailored Soil Analysis and Resistivity Surveys:

Gain detailed insights to select the best system components for your specific environment.

With EARTHRES, you’re not just implementing a cathodic protection system—you’re investing in infrastructure longevity, safety, and peace of mind.

When Integrity Matters, Clients Call EARTHRES

A natural gas pipeline operator discovered key components in their cathodic protection system were malfunctioning during routine inspections. EARTHRES stepped in to provide a comprehensive solution that included diagnostics, system repairs, optimization, and staff training.

Results:

Eliminated corrosion risks, ensuring pipeline integrity.

Reduced overall maintenance burden and costs.

Enhanced staff knowledge for future system management.

This partnership not only resolved immediate issues but also improved long-term operational efficiencies.

Learn more by checking out our CASE STUDIES on The Importance of Cathodic Protection and Closed Interval Surveys in Maintaining Gas Pipeline Integrity and 300 Mile Midstream Pipeline Network Cathodic Protection Optimization.

Case Studies

Optimizing Gas Pipeline Integrity with Advanced Cathodic Protection

Project Background Maintaining the mechanical integrity of natural gas pipelines is critical for…

300-mile Midstream Pipeline Network Cathodic Protection Optimization

The Project: Midstream Pipeline Cathodic Protection Optimization

How We Work

Let's first connect to learn more about each other and then we'll make a plan.

-

Contact Us

-

FREE Initial Consultation

-

Plan the Next Step

Contact Us

Hit the CONTACT US button and complete the form.

Someone from our Headquarters in Pipersville, PA will reach out to you to learn more about you and your project.

We know quarries and mining and serve clients all over the US and even Canada so don't let the small town PA Office location deter you.

FREE Initial Consultation

Learn About Your Concern

We will set up a time to meet via a video call to find out more about your company, your facility, and the problems you are experiencing.

- Our lead expert has over 30 years experience in this industry and knows the operations and equipment in the Mining Industry.

Plan the Next Step

Site Visit or More Research?

We will work together to determine the next best step. Often times, a site visit is scheduled for us to see your operation up close or maybe more research is needed.

Either way, we'll work together to determine what is best for your team.

What Our Clients Say About Our Services

Innovative. Practical. Reliable. Thorough.

“EARTHRES was able to provide innovative and flexible Cathodic Protection solutions that allowed us to upgrade our current Cathodic Protection System. EARTHRES handled the full design process from initial testing to final commissioning. The design process with EARTHRES was smooth and efficient."

Senior Capital Project Manager

Fortune 500 Company

“EARTHRES’ proficiency in Cathodic Protection testing, data processing, data management and reporting help to keep us ahead in integrity management program. They are our single source for Cathodic Protection testing and reporting. "

Integrity Engineer

Fortune 500 Company

"When issues were found with our current Cathodic Protection System, EARTHRES was able to work in conjunction with our internal Corrosion Engineers to find a cost effective solution that would not interrupt our process or cause any downtime. EARTHRES was able to work with the installation contractor to see the project through completion."

Facility Engineer

Fortune 500 Company

Ready to take your project to the next level?

Contact us today to learn more about how our services can benefit your operations. Let's work together to achieve success.